Filter 1 Field Applications

The engineers at Clean Air Consultants design Filter 1 products to meet the needs of each application, and our regional distributors offer their broad expertise in helping to select the equipment and options that will best fit the need. The following case studies provide examples of how Filter 1 products are at work, solving a wide range of air pollution problems.

Hydrotron Tables Eliminate Fires and Provide Comfort

Problem (Heavy Dust and Fires):

A producer of medical and electronic equipment had three large dry dust booths for keeping up with very large amounts of particulate. Being committed to a clean and safe environment for its employees, the company was seeking an improved dust collection system with a solution for problem fires resulting from sparks igniting the dust.

Solution (Hydrotron Wet Dust Collector Downdraft Tables):

The company installed seven Hydrotron downdraft tables that met all their goals:

- No more fires.

- Visibly cleaner air.

- Low profile tables allowing for easy loading of heavy parts, and for sitting or standing of the operators.

In addition, the company's process improvement engineer reported that the operators take pride in the nice look and comfort of their workstations. One of the workers commented that the work area is brighter and their clothes stay cleaner. And there was an unexpected benefit -- the water of the wet dust collector actually provided a cooler, more comfortable environment on hot days.

The maintenance staff could confirm the large amount of dust being captured by the Hydrotron tables and were happy with the ease of cleaning them out.

Flowtrons Clear the Air of Heavy Weld Smoke

Problem (Visible Haze in the Weld Shop):

A leading manufacturer of mining equipment was well within OSHA limits for air quality in their large weld facility, but wanted to provide even better protection for their workers. They wanted to remove all the visual airborne contaminants from their welding, back gouging, and grinding operations.

Solution (Flowtron Industrial Air Cleaners):

The company installed 63 Flowtron Air Cleaners -- fan-powered, self-cleaning, overhead filtration units all connected to a central vacuum collector for fully automated dust removal to drums on the floor. The system was incorporated into the existing air makeup system to produce a full-room air circulation and filtration system, eliminating potential stagnant or hazy spots. Filter 1's full-service distributor in the region, Hastings Air Energy Control, Inc., not only managed the installation but also designed an intelligent control system to monitor the performance of the system online. The company's director of health and safety reported that the results are clearly visible across the bay in the facility, and independent testing confirmed a more than 70% reduction in particulate matter. The company is pleased with the performance of the air filtration system, and also happy with the flexibility to accommodate growth and the ease of maintaining and controlling the system during seasonal climate changes.

Weldtrons Make the Difference for the High School Welding Lab

Need (Safe and Comfortable Stations for the Welding Students):

A high school welding lab had overhead hoods to capture and collect the weld smoke and fume, ducting it to a central collector outside. In the process of capturing the contaminants, the hoods pulled the smoke up around the students' faces; the school was looking to replace the system with individual backdraft welding stations.

Solution (Weldtron Backdraft Workstations):

Designed specifically for the needs of students in the welding lab, Weldtron individual booths provided comfort, safety, and ease of installation and operation. The dirty air is pulled away from the student and the 110-volt "plug-and-play" units are completely flexible in their arrangement in the lab. The lab instructor is very happy with the Weldtrons, remarking that they are quiet enough for the students to hear him as he walks down the line. Each table has a 12-sq. ft. variable height work surface, and the easy-to-install standard panel filters are designed to last for the school year.

Dustron Meets Multiple Challenges for Air Arcing Process

Problem (High Level of Noise, Sparks, and Smoke):

A heavy equipment manufacturer does air arcing (gouging) on heavy cutter blades, a process which can slant sparks 20 feet, is extremely loud, and produces heavy smoke. The company needed a control system which would facilitate the work and improve the air quality in the immediate area as well as in surrounding areas.

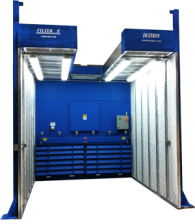

Solution (Dustron Environmental Control Booth):

Filter 1 produced a Dustron regain-air booth with many standard and custom features to serve the special needs of this demanding application:

- Large 30-ft. wide, 16-ft. deep, and 10-ft. high booth accommodates work on large parts.

- To absorb sound, sparks, and smoke, the booth is fully enclosed and insulated, and its 30,000 CFM collector is equipped with forty-two 99.9% efficient nanofiber cartridge filters. The booth is also equipped to arrest sparks with the optional "Texas Twister" inlet louvers on the front of the collector.

- The front doors and top of the booth are easily moved out of the way to receive large, heavy parts brought in by crane.

Contact Our Engineers

Unsure which product is the right fit for your facility? Have a question about how we can customize our products? Fill out this form and one of our experts will respond to you as soon as possible.