Dustron DB Dust Containment Booth

The Original Ultra-Efficiency Cartridge Dust Collector Booth

The Filter 1 Advantage

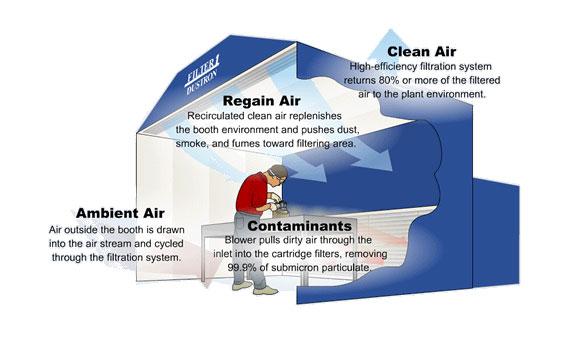

One of the first cartridge dust collector booths to implement the innovative regain of air principle, the Filter 1 Dustron DB Dust Contaminant Booth increases worker comfort and visibility in the critical work areas. Capitalizing on the multiplied ventilation effect of "pushing" clean air out across the front of the booth as the blower "pulls" contaminated air into the filters, the Dustron provides velocities of 400/800 FPM at the center zone of the booth where the dust is being generated. With Clean Air Consultants' fully implemented, fully adjustable Push/Pull Regain Air, the Filter 1 Dustron enhances the conditions and productivity of operations within the booth.

Noise Control

The Filter 1 Dustron has built-in sound absorption benefiting the workers inside as well as outside the booth:

- Solid Construction. Standard booth built with 18 gauge steel walls and ceiling.

- Advanced Core Insulation. Sound-absorbing mats of two-inch fiberglass compressed to one inch.

- Outer Layer. Further enhancement of sound attenuation with 5 mils aluminized vinyl-impregnated fiberglass cloth covering of mat.

Enhanced Work Environment

The Filter 1 Dustron is designed to provide optimal conditions for large industrialoperations where dust and/or noise are a problem.

- Freedom of Movement. The capture velocity provided throughout the booth means that workers are not "tied" to a limited surface space, source capture arm, or vacuum hose.

- Visibility. The Filter 1 Dustron's effective source capture of smoke, fumes, and dust provides consistent visibility in the work areas of the booth. In addition, the Filter 1 Dustron is well-lit with sealed and gasketed dust-tight fluorescent lights.

- Safety/Productivity. Many dust booths provide containment without achieving effective environmental control within the booth. The Filter 1 Dustron is designed to effectively capture contaminants for the comfort and health of the booth workers.

Fine to medium particulate (as well as fumes and smoke) from:

- Wood

- Metal

- Composites

- Plastics

- Fiberglass

- Dry powder

- Cement

- Toner

The Filter 1 Dustron Environmental Control Booth is utilized for a broad spectrum of industrial contaminants and processes, including:

When live sparks are created by grinding on steel or welding, our fire-retardant cartridges should be further protected by the optional spark trap and solid-state spark detector.

The Dustron provides controlled air workspaces in a large variety of industries, including:

- Military and commercial aircraft manufacturing

- National laboratories

- Helicopter manufacturing

- Mechanical component production

- Medical equipment manufacturing

- Musical instrument crafters

- Steel production

- Air Force base operations

- Electronics manufacturing

- Auger/Vacutron dust removal

- High-temperature cut-off

- Texas Twister™ spark trap

- VFC for soft-start and low velocity during cleaning

- Unlimited width and depth

- Crane slot

- Open top

- Removable top

- Tilt-up top

- HEPA after filters

- Carbon after filters

Dustron DB Series

| Model | Cartridges | HP | HxDxW | Filter Sq Ft |

| DB-8-12-7.5 | 12 | 7.5 | 90" x 8' x 8' | 3,000 |

| DB-10-16-7.5 | 16 | 7.5 | 90" x 8' x 10' | 3,500 |

| DB-12-18-15 | 18 | 15 | 90" x 8' x 12' | 4,500 |

| DB-16-24-2x7.5 | 24 | 2x7.5 | 90" x 8' x 16' | 6,000 |

| DB-20-28-2x7.5 | 28 | 2x7.5 | 90" x 8' x 20' | 7,000 |

| DB-24-36-2x15 | 36 | 2x15 | 90" x 8' x 24' | 9,000 |

| DB-30-42-3x7.5 | 42 | 3x7.5 | 90" x 8' x 30' | 10,500 |

Contact Our Engineers

Unsure which product is the right fit for your facility? Have a question about how we can customize our products? Fill out this form and one of our experts will respond to you as soon as possible.